We are happy to share customer tour videos for multiple vertical integrated aeroponic cultivators. Each of these teams run pristine operations in very clean highly productive facilities. These facilities range from 10,000-30,000 square feet in size.

Jim Strain (jrstrain_cannabis on Instagram) is the Master Grower at Dycar Pharmaceuticals in Canada. Jim has long experience in cultivation, over his long career. After proving himself in all types of grow methods and media, Dycar is delivering spectacular roots and superior flower to Canadian customers across the nation. Check out his latest progress and the Dycar Pharma portfolio when you have the opportunity. Absolutely great work.

DanCann Pharma has qualified for commercial production with zero irradiation above European pharma standards for medicinal manufacturing. DanCann prides themselves in producing pure and perfectly sterile aeroponic flower to the highest standards. Their focus on meeting the needs of European patients is impressive and lasting. Aeroponics enables them to deliver unspoiled products without any contamination or degradation from irradiation.

420Kingdom, in the highly competitive California market, retrofitted a building with precision aeroponics. They calculated the ideal environmental controls and started growing. They tell us they learned more about their recipes to improve yield and potency. Turning the crank, their team added SOPs for water quality, humidity cycles, IPM, and post harvest cleaning.

DanCann Pharma, a medicinal cannabis company based in Denmark, is building out their entire capacity with 1, 2, and 4-Layer AEtrium Systems. With full approval from the Danish Medicines Agency, DanCann is delivering to Germany and Poland, currently sold out from 2023 to 2025 in their current facilities.

No one talks about cleaning but it is critical to the spectacular potency metrics, spectacular yields, and profits that 420Kingdom delivers. Great genetics get the results into the high twenties but with precision execution and the Guardian Grow Manager, the team pushes total cannabinoids to 43% and beyond. Watch their video for a brief tour through their methods.

FarmaGrowers in South Africa is another fascinating team. From outland farmers to precision medicinal plants with the highest quality, they are one of the few global vendors certified to ship to any global market with the highest standards.

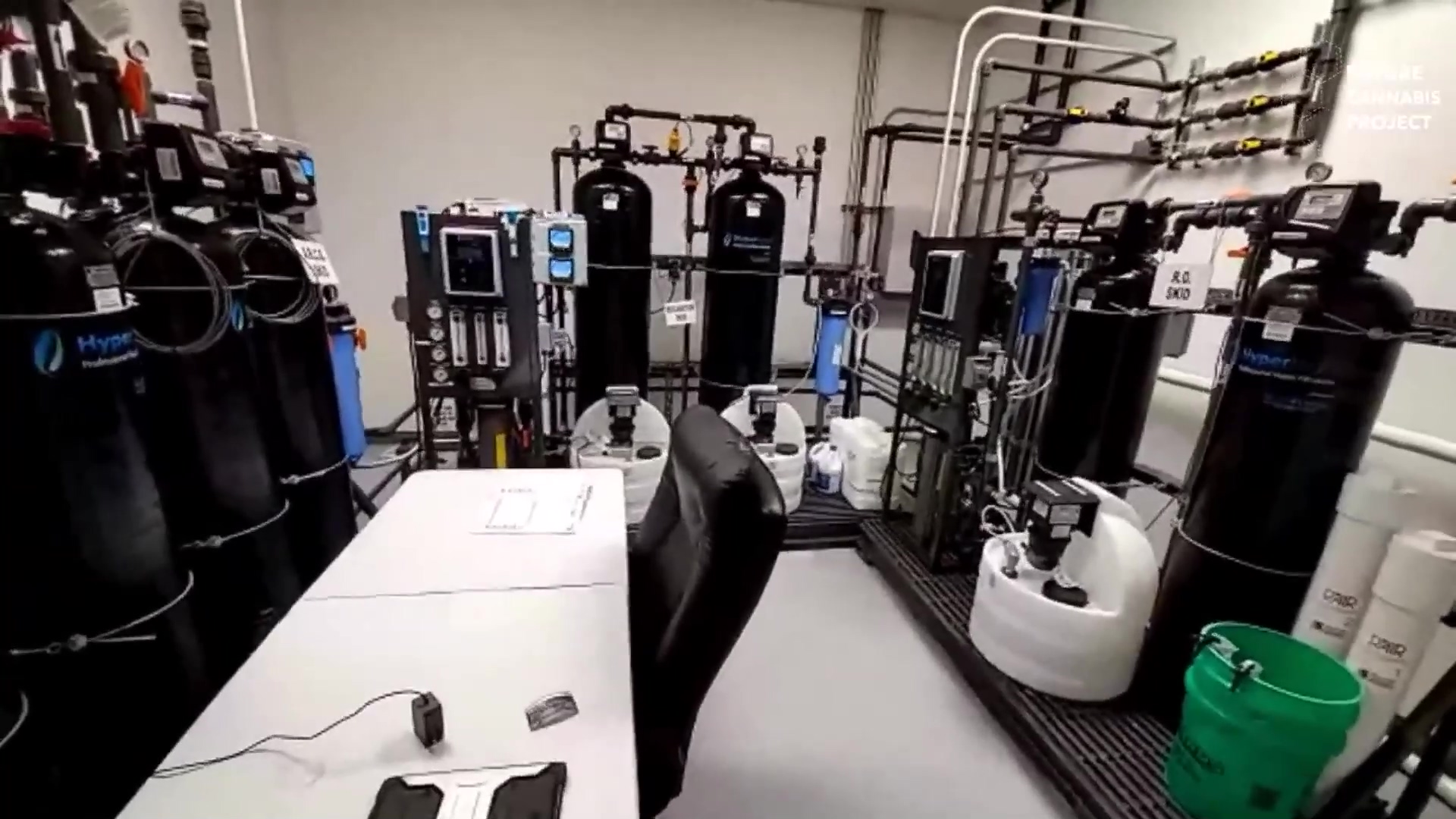

Leveraging sophisticated HVAC systems and clear water quality, FarmaGrowers' entire operation is pristine and structured for efficient execution. Watch their video to take a look at their state-of-the-art facility.

Clean water and clean systems are a requirement for global export qualification. Sterile, sealed, positive airflow systems may not be glamorous, but they do wonderous things with aeroponic roots. Use these methods and produce faster, cleaner, Flower that your customers will desire and buy at a premium.

RAIR is a vertically integrated aeroponic cultivator located in Michigan, USA. Ashley Hubbard is their director of cultivation and manages a highly automated state-of-the-art 22,000 square foot canopy facility. They retail top shelf flower and consumables through their five dispensaries, and here, Ashley will give you a personal tour of their facility and grow procedures.

Their operation leverages precision aeroponics to produce the cleanest flowers possible with a continuous harvest flow from mothers to clone/veg to flower. Their production operation is fully contained, recycles all of it's used water and nutrients, and uses zero soil. Their environmental and nutrient recipes are optimized for each variety with real time adjustments for the highest terpene optimization for their consumers. This is one of the most impressive operations we have seen and we are delighted to share it with you.

You can also view our "Water Quality" webinar here.:

RAIR starts their grow cycle with beautiful healthy Mother plants for all of their genetics. Ashley Hubbard reviews their process in their multi-cycle Mothers room for 9 different strains in this video. RAIR regularly cycles through their Mother plants to run with the very fast growth in the AEtrium-4 Tall Plant System. Their Mothers supply cuttings each week to the next phase of their production: Cloning. It is fully contained, recycles all of it's used water and nutrients, and uses zero soil.

You can also view "Give Your Plants The Best Start" webinar here.

It was useful as part of this flow to insert a short demonstration of how to properly take cuttings from a Mother plant. For that purpose, we have Karl Kulik giving the best approach to select and take a branch cutting. This cutting will root in the AEtrium SmartFarm in 3-5 days and it will be a bushy 12 inch tall rooted Clone in 10-12 days.

This segment covers the RAIR aeroponic Clone & Veg room where they take cuttings from their mother room and grow them into rooted Clones, pinch off the tops, and in a total of 4 weeks deliver a bushy Veg plant to their next available Flower room. Zero soil is used throughout the facility.

Their continuous harvest process has a capacity of more than 300,000 clones per year in four 48-tray SmartFarm systems with the growth and harvest process staged and synchronized for their next available flower room.

You can also view Bulking Up Your Plants: Vegetative Plant Production here -->

After the Clone & Veg cycle in the AEtrium-2.1 SmartFarm in the previous episode, Ashley Hubbard and team show us what week 3 of Flower looks like in one of their 2,000 square foot Flower rooms. After a few days of environmental transition, they flip the light cycle to 12 hours ON/12 hours OFF and they are in Flower.

The plants grow and stretch at this stage and Ashley explains their crop steering methods and one of their A/B tests in process.

You can also view Flower Blooming

Part 1: Cultivation Tips On Your Way To Bud Set here -->

The team at RAIR captures thousands of data points automatically and consistently uses the Guardian Grow Manager to execute and monitor A/B grow recipe testing. Their environmental and nutrient recipes are optimized for each variety with real time adjustments for the highest terpene optimization for their consumers. This is one of the most impressive operations we have seen and we are delighted to share it with you.

You can also view our OnDemand Guardian webinars:

Ashley and team continue their aeroponic facility tour with the bonus of 9 strains in beautiful Flower. Join them as they walk you through one of their Flower rooms at the end of week 6. You can appreciate the attention to detail and the cleanliness of this stage in their flower development in zero soil. AEssenseGrows AEtrium-4 aeroponics are optimized for each Flower room. Ashley reviews her unique grow recipes for each strain. She uses this to increase cannabinoid potency and enhance terpene profiles through crop steering techniques. Their production operation is fully contained, recycles all of it's used water and nutrients. This is one of the most impressive operations we have seen and we are delighted to share it with you.

You can also view Flower Blooming

Part 2: Bud Swell To Post Harvest -->

Some of this content was originally captured by the Future Project, with footnotes by episode.